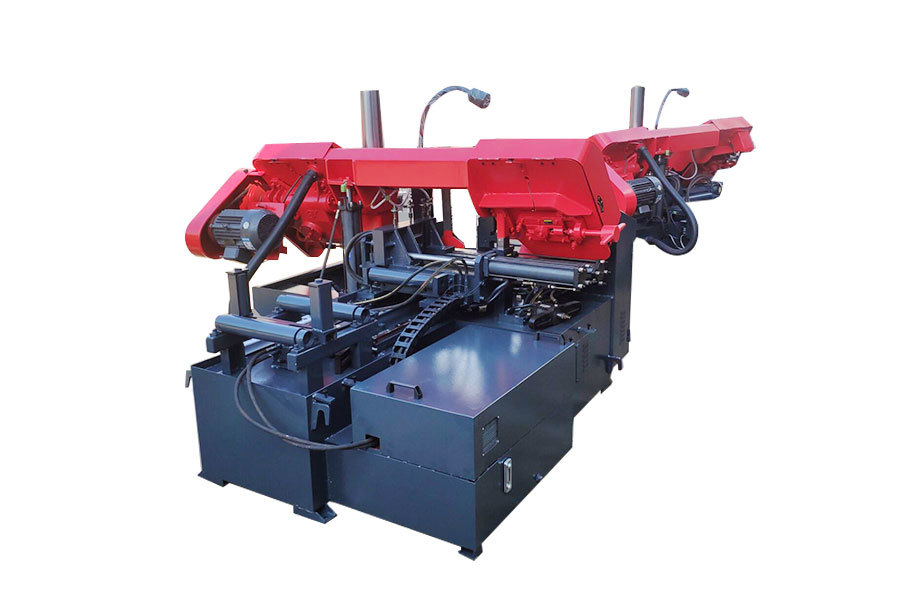

GB4240

A professional research and manufacture of sawing machinery production enterprises, enterprises with strong technical force, sophisticated mechanical processing equipment and advanced production technology, is one of the key production enterprises of national band sawing machine.

Classification:

Main column horizontal metal band sawing machine

Key words: GB4240

Product Description

The main components of the band sawing machine include:

Bottom seat; Bed and upright post; Saw beam and transmission mechanism; Guiding device; Workpiece clamping; Tensioning device; Feeding frame; Hydraulic transmission system; Electrical control system; Lubrication and cooling system; Band sawing machine base: The band sawing machine base is a box-shaped structure formed by welding steel plates. The bed and upright posts are fixed on it. The inner cavity of the circular sawing machine base has a large space. The front left side is an electrical button control box, and the right is an electrical distribution board box, the hydraulic oil tank welded by steel plates in the middle is equipped with a hydraulic pump station and hydraulic pipelines in the cavity. The right side is a cooling cutting fluid tank and a water pump, and there are anchor bolt holes in the bottom four corners.

band sawing machine bed composition:

The band sawing machine bed is cast iron and fixed on the base. The column is composed of a large and small cylinder. The large circular column is used as the guide rail of the saw frame to support the up and down movement of the saw beam and ensure accurate guidance. The small cylinder plays an auxiliary role to ensure the normal cutting of the saw blade. The middle is a clamping vise and a manual feeding mechanism. The front of the vise is connected with a worktable for receiving finished parts. The clamping device on the left is a clamping screw rod that passes through the inner hole of the hydraulic clamping cylinder rod, and rotates the handwheel or presses the button to make the left jaw move left and right.

band sawing machine saw beam and transmission mechanism:

It is cut, formed and welded by thick steel plate and has strong rigidity. A worm gear box is fixed on the right rear side. The worm wheel in the box is fixedly connected with the driving wheel on the saw beam. The two rotate synchronously. The left side is the passive wheel and the saw blade tension position. The rotary motion of the saw blade is driven by the main motor, belt pulley and worm gear through two-stage variable speed transmission to the driving wheel, and then driven by the driving wheel and the saw blade to drive the passive wheel. The saw blade runs at three speeds.

band sawing machine saw blade guide device:

The guide device is installed on the sawing beam support plate and consists of left and right guide arms and guide heads. The left and right guide arms can move along the dovetail (or the right guide arm is fixed on the column sleeve), and the distance between the two guide arms is adjusted to be about 40mm wider than the workpiece size. The guide device is used to change the installation angle of the saw blade so that the saw blade is perpendicular to the worktable. In order to ensure the cutting accuracy of the saw blade and reduce vibration, a set of guide wheels (rolling bearings) and wear-resistant guide blocks are installed on the left and right guide arms. The back of the saw blade also has a wear-resistant alloy guide block.

Clamping mechanism:

The right vise is fixed on the bed, the clamping screw rod passes through the inner hole of the hydraulic clamping cylinder, and the hydraulic band saw machine is connected by the screw rod. The left vise moves left and right along the guide rail, and is connected when the left vise is 10-30mm away from the workpiece. Press the clamp of the control panel by hand to tighten or loosen the clamp to clamp or loosen the workpiece. Tensioning device

Tensioning device:

It is composed of a skateboard seat, a skateboard, a screw rod, etc. When the saw blade is to be tightened, the saw blade can be tightened by rotating it clockwise with a torque wrench, and it is in working condition. If the sawing machine is in a long-time shutdown state, the torque wrench rotates the saw blade counterclockwise to loosen, and the saw blade can be replaced with a new one after loosening the saw blade.

| Sawing capacity (mm) | 500*400 |

| Linear speed of band saw blade (m/min) | 22/43/64/72 |

| Band saw blade specification (mm) | 1.3*41*4700 |

| Main motor power (kw) | 4 |

| Hydraulic motor power (kw) | 0.75 |

| Cooling machine power (kw) | 0.04 |

| main drive structure | Turbine |

| Saw band tensioning method | Manual |

| Feeding mode | Auxiliary track |

| Clamping mode | hand fluid binding |

| Machine Size | 1000*2400*1650 |

About metal band sawing machine, alloy band saw blade and other equipment and application industry and advantages

Overview of 1. metal band sawing machine and alloy band saw blade

Metal band sawing machine is a kind of equipment that uses metal band saw blade for cutting, which is suitable for cutting various materials. Alloy band saw blade is the key component, made of high strength alloy material, has excellent wear resistance and fatigue resistance.

Application industry of 2. metal band sawing machine

1. Wood processing industry: used for wood, furniture and other wood precision cutting.

2. Metal material processing industry: used for cutting metal pipes and profiles.

3. Plastics and composite materials industry: used for cutting plastic plates and composite materials.

Application and Advantages of 3. Metal Band Saw Blade

Metal band saw blades are suitable for fine cutting of various materials, and their advantages are as follows:

1. Efficient cutting: The metal band saw blade adopts sharp saw tooth design, which can realize efficient and accurate cutting.

2. Wide application range: suitable for cutting a variety of materials, such as wood, metal, plastic, etc.

3. Long life: It is made of high-strength alloy material and has a long service life.

Application and Advantage of 4. High Speed Intelligent Circular Saw Machine

The high-speed intelligent circular saw machine is mainly used for precision round hole cutting of wood, metal and other materials. Its advantages include:

1. High-precision cutting: to achieve high-precision round hole cutting, to meet a variety of precision machining needs.

2. Intelligent operation: with automation, intelligent operating system, improve production efficiency.

3. High-speed operation: high-performance motor is adopted to realize high-speed operation and improve processing efficiency.

Comprehensive advantages of 5. application industry

1. Wood processing: improve cutting efficiency and reduce processing costs.

2. Metal processing: to achieve high-precision, high-efficiency cutting, improve product quality.

3. Plastics and composite materials processing: to adapt to the cutting needs of a variety of materials, improve production flexibility.

4. Other industries: such as construction, stone and other industries, but also through the metal band sawing machine and other equipment to achieve efficient and accurate cutting.

In short, metal band sawing machine, alloy band saw blade and high-speed intelligent circular saw machine and other equipment in the wood, metal and other materials processing industry has a wide range of application prospects. Its high efficiency, precision and wide applicability have brought significant advantages to various industries and improved production efficiency and product quality.

Recommend Products

The main components of the band sawing machine include: Bottom seat; bed, column; saw beam and transmission mechanism; guide device; workpiece clamping; tensioning device; feeding frame; hydraulic transmission system; electrical control system; lubrication and cooling system;

Specializing in the production of CNC band sawing machine, horizontal, vertical, column, gantry series automatic, semi-automatic metal band sawing machine.

Specializing in the production of CNC band sawing machine, horizontal, vertical, column, gantry series automatic, semi-automatic metal band sawing machine.

Specializing in the production of CNC band sawing machine, horizontal, vertical, column, gantry series automatic, semi-automatic metal band sawing machine.

Welcome Your Message Consultation