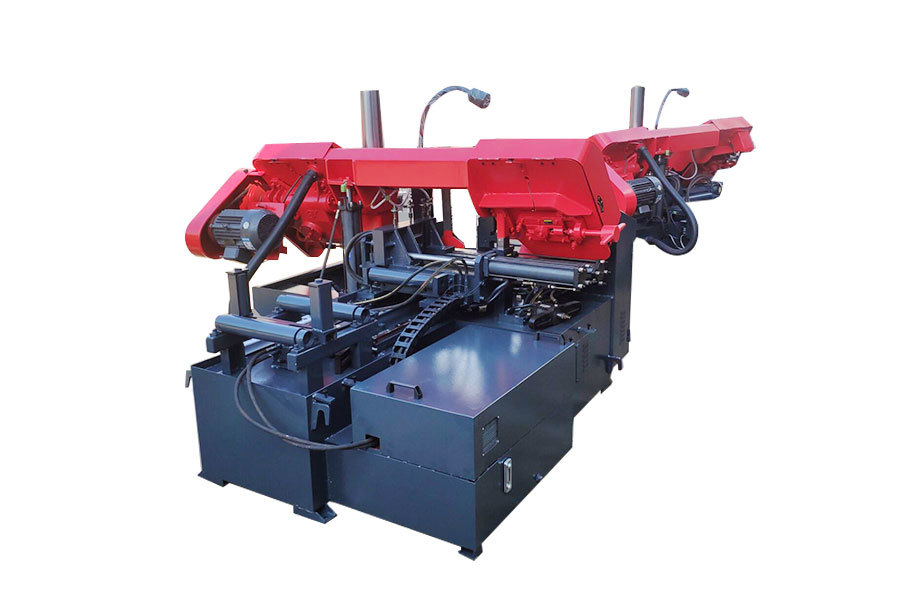

GB42100

A professional research and manufacture of sawing machinery production enterprises, enterprises with strong technical force, sophisticated mechanical processing equipment and advanced production technology, is one of the key production enterprises of national band sawing machine.

Classification:

Double column gantry type metal band sawing machine

Key words: GB42100

Product Description

| Sawing capacity (mm) | ● 1000 ■ 1000*1000 |

| Linear speed of band saw blade (m/min) | 15-60 |

| Band saw blade specification (mm) | 1.6*67*9700 |

| Main motor power (kw) | 11 |

| Hydraulic motor power (kw) | 3.75 |

| Cooling machine power (kw) | 120 |

| main drive structure | Turbine |

| Saw band tensioning method | Hydraulic |

| Feeding mode | Sled/Drum |

| Clamping mode | Front and rear hydraulic vise |

| Machine Size | 3100*4500*2800 |

The key points of cutting steel by Lichi band sawing machine:

When using band saw to cut H-steel, I-steel, angle steel and channel steel, it is necessary to ensure that the inclination is not cut. Once the material is cut obliquely or dug, the subsequent material welding process will be affected, resulting in welders having to polish excess materials or increase filling materials. What's more, it may lead to re-blanking or material waste, which is time-consuming and expensive. Therefore, when we saw the profile, we should pay attention to the following matters:

1. Sawing machine maintenance

Pay attention to the daily maintenance of the sawing machine. If there is a problem with the feed system and the main drive system, it will significantly shorten the use time of the band saw, and it will also cause the saw blade to cut easily.

2. Pay attention to setting the sawing parameters

According to the band saw blade manufacturer or sawing machine manufacturer's parameter guidance table to set the sawing parameters, generally less than 10mm thin-walled profiles, its sawing efficiency is only about 20% of the same height of the solid material, its feed speed is mainly to consider the average cutting load per tooth. H steel, channel steel are generally low carbon steel or structural steel extrusion processing, the following are the two typical materials sawing parameters:

H steel I-beam sawing parameter table:

For other materials, the speed is generally set high when the material is soft, and the line speed is set low when the material is hard.

In addition, pay attention to the material clamping to be positive, and ensure that the feeding roller will send the material to the position.

3. Set the band saw tension correctly

General sawing machine sawing steel, the tension is set between 170KN/cm2 ~ 220KN/cm2, the tension is too small will cause the strength of the beam is not enough, band saw fatigue and oblique cutting; and the tension is too large and may cause the band saw early fracture, weld fracture, tooth groove cracking, and may cause the main bearing of the saw wheel to wear too fast.

4. Pay attention to cut in from the lower weld of the weld

If some section steels have welds, be careful not to cut into the upper welds. Otherwise, the weld surplus height protruding from the upper welds will easily cause sudden increase of band saw load in operation and may cause tooth pulling failure.

5. Pay attention to the clamping method

When clamping, it is necessary to control the cut workpiece not to slide or rotate. If a single workpiece moves back and forth during the sawing process, it may also cause the band saw to pull teeth. The general clamping method of section steel is as follows:

6. Correct use of cutting fluid

The cutting fluid can not only cool, but also prevent the formation of chip deposits at the tooth tip. The cutting fluid should cover the entire sawing path of the workpiece. The cutting fluid will volatilize during use. The concentration of the cutting fluid should be kept at about 5% as far as possible. The concentration of the new fluid should be proportioned before being added to the cutting fluid pool.

7. Band saw running-in

The new band saw needs running-in at the beginning of sawing section steel. The running-in of sawing section steel is especially important, because cutting this material vibrates greatly, which is easy to cause the tooth tip of the new saw blade to collapse slightly. The author's suggestion is to first adjust the feed speed of the band saw to 10% of the normal value during the initial sawing, instead of 50% set under the regular running-in mode (because the feed speed of section steel is much faster). The line speed does not need to be adjusted, and the feed speed is gradually increased to 100 during the sawing process. The life of a properly run-in saw blade may be about twice the life of an improperly run-in saw blade.

8. Select the appropriate saw blade

At present, there are tensile teeth and sharp tooth saw blades on the market. For thin-walled steel with a thickness of less than 10mm to be cut, tensile teeth are mainly selected. For thin-walled steel with a thickness of more than 10mm, tensile teeth and turtle back teeth can be selected according to the efficiency requirements and sawing conditions. For occasions where teeth are easy to be pulled, tensile teeth and turtle back teeth can also be selected.

If the material is stainless steel, alloy steel, you can choose a smaller pitch of the sharp teeth, because its feed speed is significantly reduced, such as sawing 2mm wall thickness of stainless steel pipe, the use of 6/10 sharp teeth can also be very good sawing effect. For the section steel made of medium and low carbon steel, it is not recommended to use the tooth type with large front angle.

If the pursuit of high efficiency sawing, low-end saw blades often back strength and processing accuracy can not meet the requirements, it is recommended to select LB-AA and above product series.

In the selection of tooth pitch, the selection of a larger tooth pitch can improve the sawing efficiency, and the selection of a smaller tooth pitch, the machining surface of the workpiece is smoother.

If there is a serious clamping or card saw phenomenon, need to order to increase the amount of teeth products. Generally, this kind of card saw phenomenon is easy to appear in sawing medium and large I-beam.

9. The choice of sawing machine

Lichi sawing machine is sold with special sawing machines for cutting section steel. If units with more H-steel, I-steel and channel steel are processed, it is recommended to select a sawing machine with a certain inclination angle on the head. This sawing machine can make the load of the saw blade more uniform in the whole sawing stroke, prevent the tooth groove from being unsmooth when cutting to the web position, and keep the saw seam smaller.

About metal band sawing machine, alloy band saw blade and other equipment and application industry and advantages

Overview of 1. metal band sawing machine and alloy band saw blade

Metal band sawing machine is a kind of equipment that uses metal band saw blade for cutting, which is suitable for cutting various materials. Alloy band saw blade is the key component, made of high strength alloy material, has excellent wear resistance and fatigue resistance.

Application industry of 2. metal band sawing machine

1. Wood processing industry: used for wood, furniture and other wood precision cutting.

2. Metal material processing industry: used for cutting metal pipes and profiles.

3. Plastics and composite materials industry: used for cutting plastic plates and composite materials.

Application and Advantages of 3. Metal Band Saw Blade

Metal band saw blades are suitable for fine cutting of various materials, and their advantages are as follows:

1. Efficient cutting: The metal band saw blade adopts sharp saw tooth design, which can realize efficient and accurate cutting.

2. Wide application range: suitable for cutting a variety of materials, such as wood, metal, plastic, etc.

3. Long life: It is made of high-strength alloy material and has a long service life.

Application and Advantage of 4. High Speed Intelligent Circular Saw Machine

The high-speed intelligent circular saw machine is mainly used for precision round hole cutting of wood, metal and other materials. Its advantages include:

1. High-precision cutting: to achieve high-precision round hole cutting, to meet a variety of precision machining needs.

2. Intelligent operation: with automation, intelligent operating system, improve production efficiency.

3. High-speed operation: high-performance motor is adopted to realize high-speed operation and improve processing efficiency.

Comprehensive advantages of 5. application industry

1. Wood processing: improve cutting efficiency and reduce processing costs.

2. Metal processing: to achieve high-precision, high-efficiency cutting, improve product quality.

3. Plastics and composite materials processing: to adapt to the cutting needs of a variety of materials, improve production flexibility.

4. Other industries: such as construction, stone and other industries, but also through the metal band sawing machine and other equipment to achieve efficient and accurate cutting.

In short, metal band sawing machine, alloy band saw blade and high-speed intelligent circular saw machine and other equipment in the wood, metal and other materials processing industry has a wide range of application prospects. Its high efficiency, precision and wide applicability have brought significant advantages to various industries and improved production efficiency and product quality.

Recommend Products

The main components of the band sawing machine include: Bottom seat; bed, column; saw beam and transmission mechanism; guide device; workpiece clamping; tensioning device; feeding frame; hydraulic transmission system; electrical control system; lubrication and cooling system;

Specializing in the production of CNC band sawing machine, horizontal, vertical, column, gantry series automatic, semi-automatic metal band sawing machine.

Specializing in the production of CNC band sawing machine, horizontal, vertical, column, gantry series automatic, semi-automatic metal band sawing machine.

Specializing in the production of CNC band sawing machine, horizontal, vertical, column, gantry series automatic, semi-automatic metal band sawing machine.

Welcome Your Message Consultation