Instructions on the use of automatic band sawing machine

Release time:

2014-03-03

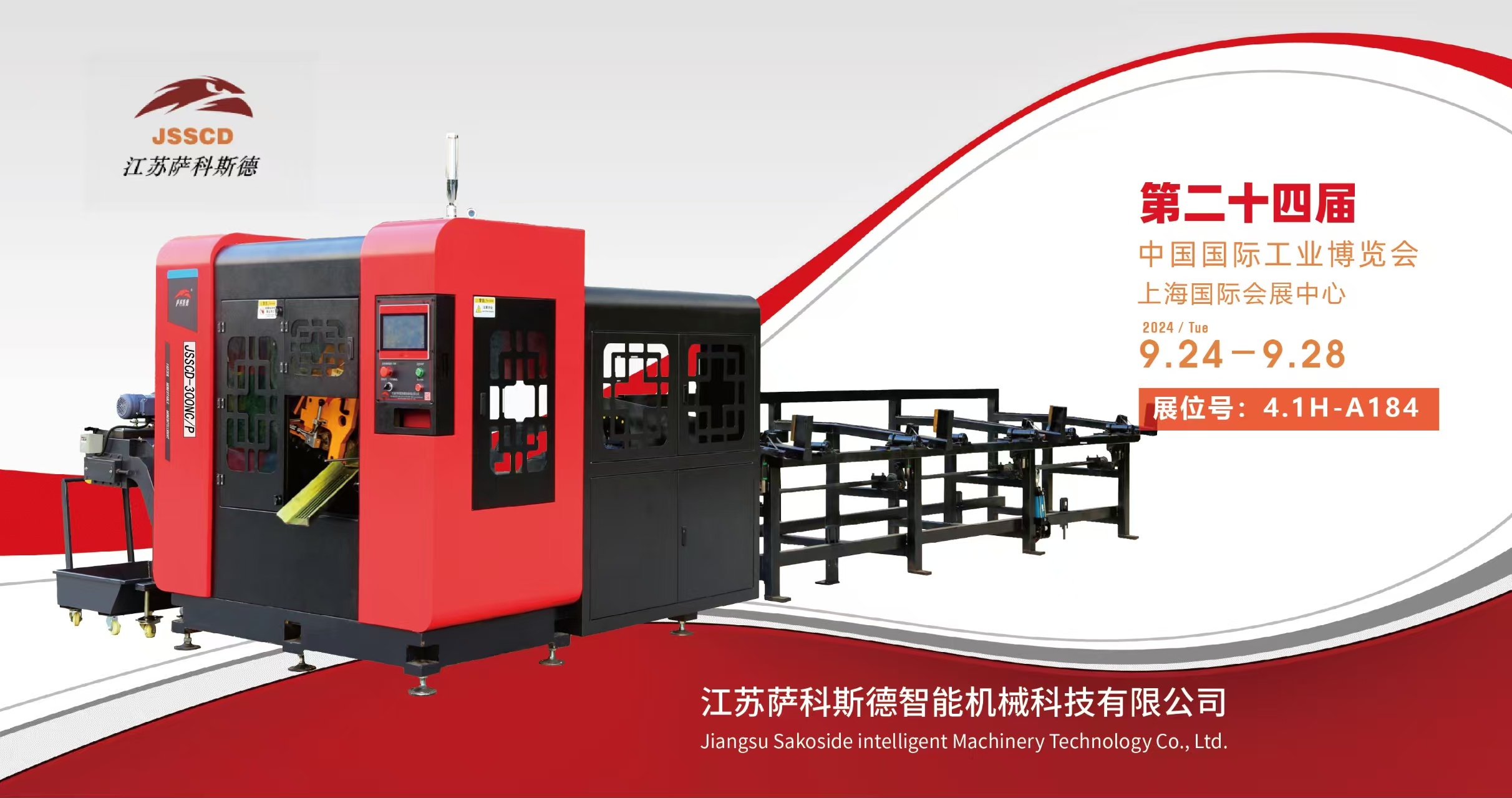

The main passive wheel guard, belt pulley guard, band saw blade guard and receiving table of the full-automatic band sawing machine produced by Jiangsu Lichi CNC Machine Tool Manufacturing Co., Ltd. are all safety protection devices, which should be used correctly during operation. Before opening the full-automatic band sawing machine, the belt pulley guard must be installed, and the two saw belt pulley guards must be lowered and covered. When the sawing material is long, the lengthened feeding roller table must be selected; when the sawing material is long, the lengthened receiving roller table must be selected. The guide of the full-automatic band saw machine and the guard of the band saw blade should be as close to the workpiece as possible, and the adjustment must be carried out without starting the main motor. After adjustment, the locking handle or screw should be tightened. Automatic band sawing machine grounding to be reliable. Operators should be trained to enable them to safely complete the various operations of the sawing machine. Clamping the workpiece must be reliable. When the full-automatic band saw machine is working, it is strictly forbidden to wear gloves; but when loading and unloading the band saw blade, you must wear gloves. Fully automatic band sawing machine in extremely special circumstances, can also be stopped by turning off the main switch on the distribution box. The main power supply must be turned off in one of the following situations: when adjusting the speed of the saw band, when replacing the band saw blade, during maintenance, before opening the distribution box, and after the task is completed and stopped. Check before the test run of the full-automatic band saw machine: whether the machine is installed correctly, horizontally and stably; Whether all safety protection devices are used as required; Whether the locking screw of the saw bow is removed; When the full-automatic band saw machine is sawing, it is strictly prohibited to extend the hand or other parts of the body into the sawing point or vice area. In the course of operation, once an abnormal situation occurs, the emergency stop is generally realized by pressing the total stop button on the control panel.

The main passive wheel guard, belt pulley guard, band saw blade guard and receiving table of the full-automatic band sawing machine produced by Jiangsu Lichi CNC Machine Tool Manufacturing Co., Ltd. are all safety protection devices, which should be used correctly during operation. Before opening the full-automatic band sawing machine, the belt pulley guard must be installed, and the two saw belt pulley guards must be lowered and covered. When the sawing material is long, the lengthened feeding roller table must be selected; when the sawing material is long, the lengthened receiving roller table must be selected. The guide of the full-automatic band saw machine and the guard of the band saw blade should be as close to the workpiece as possible, and the adjustment must be carried out without starting the main motor. After adjustment, the locking handle or screw should be tightened.

Automatic band sawing machine grounding to be reliable. Operators should be trained to enable them to safely complete the various operations of the sawing machine. Clamping the workpiece must be reliable. When the full-automatic band saw machine is working, it is strictly forbidden to wear gloves; but when loading and unloading the band saw blade, you must wear gloves. Fully automatic band sawing machine in extremely special circumstances, can also be stopped by turning off the main switch on the distribution box.

The main power supply must be turned off in one of the following situations: when adjusting the speed of the saw band, when replacing the band saw blade, during maintenance, before opening the distribution box, and after the task is completed and stopped. Check before the test run of the full-automatic band saw machine: whether the machine is installed correctly, horizontally and stably; Whether all safety protection devices are used as required; Whether the locking screw of the saw bow is removed; When the full-automatic band saw machine is sawing, it is strictly prohibited to extend the hand or other parts of the body into the sawing point or vice area.

In the course of operation, once an abnormal situation occurs, the emergency stop is generally realized by pressing the total stop button on the control panel.