How to maintain domestic band sawing machine?

Release time:

2022-07-12

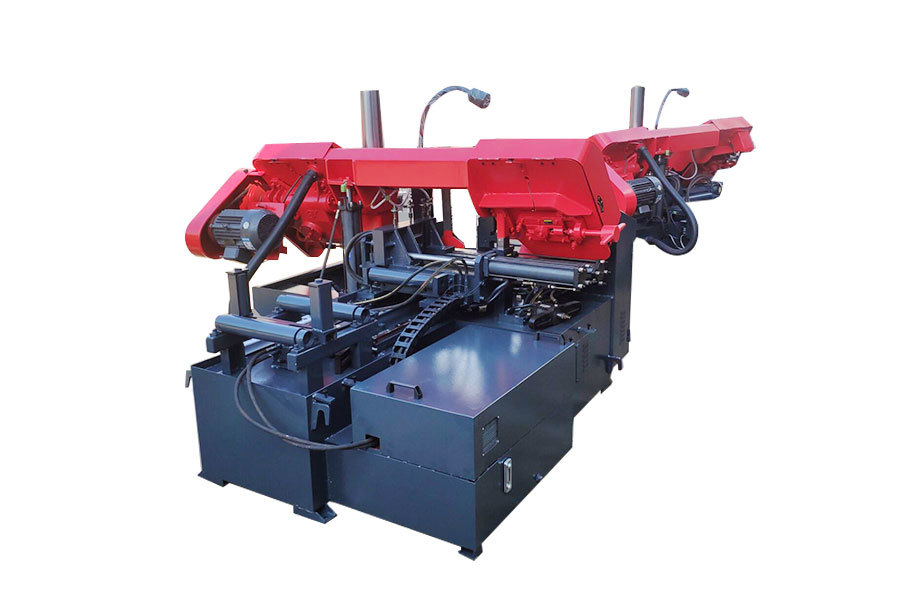

Any instrument and equipment need regular inspection and maintenance, in order to improve the service life of the equipment and production efficiency, band sawing machine is the same, need regular inspection, then, domestic band sawing machine how to maintain?

How to maintain domestic band sawing machine?

Any instrument and equipment need regular inspection and maintenance, in order to improve the service life of the equipment and production efficiency, band sawing machine is the same, need regular inspection, then, domestic band sawing machine how to maintain?

How to maintain domestic band sawing machine?

1. internal and external maintenance

1.15 minutes before leaving work, tidy up the sawing machine and auxiliary tools, wipe the machine tool, remove iron filings, dust and oil stains, and relax the saw belt.

2. Check whether the screws, nuts, handles and handle balls of each component are loose or damaged. Keep the sawing machine in good condition.

3. Regularly remove the cover and wipe the internal parts to make the inside and outside of the sawing machine clean and intact to prevent corrosion.

2. hydraulic system and transmission system

1. Wipe the guide rail and sliding surface 15 minutes before leaving work.

2. Regularly clean the worm gear box, adjust the fit clearance of each transmission part, and tighten the connecting bolts and nuts of each part.

3. lubrication system

1. Before starting the band saw, lubricate all parts of the saw according to the lubrication instructions.

2. Regularly check the concentration and amount of lubricating oil in the worm gear box of the sawing machine, and whether the emulsified cutting fluid in the water tank is in place.

3. Regularly clean the lubrication mechanism of each part to keep the oil path unblocked and no oil leakage.

Before starting the 4., check whether the electrical equipment, motor, cable, switch and lighting are in good condition and grounded stably.

In order to keep the sawing machine in good condition, it is necessary to maintain the sawing machine regularly. After the end of each day's work, clean the iron filings accumulated on the machine to stop the saw belt, turn on the cooling water switch, and clean the workbench with a cooling water spray gun. After cleaning, lower the saw bow to a lower position.

1. Before daily maintenance and operation of the machine, check according to the following procedures:

2. Check the hydraulic oil gauge. Does the hydraulic fluid exceed the L red line? When the hydraulic fluid is lower than the L red line, it is necessary to add a proper amount of No.32 anti-wear hydraulic fluid and cross the red line;

3. Check whether the coolant water meter exceeds the red line. When the cooling water is lower than the L red line, appropriate cooling water needs to be added;

4. Check whether the saw belt is located on the left and right saw wheels and between the front and rear tungsten steel guide rails;

5. Check whether the wire brush is located at the root of the sawtooth;

6. Add mechanical oil to the guide rail of the movable clamp on the bed table;

7. Add mechanical oil to the floating clamp guide rail of the feed bed worktable;

How to choose to buy domestic band sawing machine?

1. The service life and later maintenance of the band saw machine are very important. There are many counterfeit products in the sawing machine market now. The appearance of the band saw machine looks similar, but the quality and service life of the saw machine are far from each other, and the repair rate is high.

2. The stability and sawing speed of the horizontal band sawing machine are the key. Some band saws use worm gear transmission, which has the characteristics of high transmission efficiency, large transmission ratio, low noise, small oscillation, reasonable structure, beautiful appearance, and coordination of each saw frame. It is composed of guide wheel seat, tungsten steel plate and anti-noise wheel, and is equipped with cooling nozzle. The tungsten sheet is sintered from hard alloy and steel plate, with high strength and good wear resistance. The saw frame lifting of the band saw machine adopts the structure design of large diameter cast pipe chrome plating and square steel guide rail. The main lifting cylinder completes the sawing, which ensures the stability and cutting speed of the band saw machine.

3. The use and life of the sawing blade. A band saw machine with high stability has high applicability to saw blades and saves band saw blades.

4. Whether the after-sales and maintenance of the band saw machine are timely.