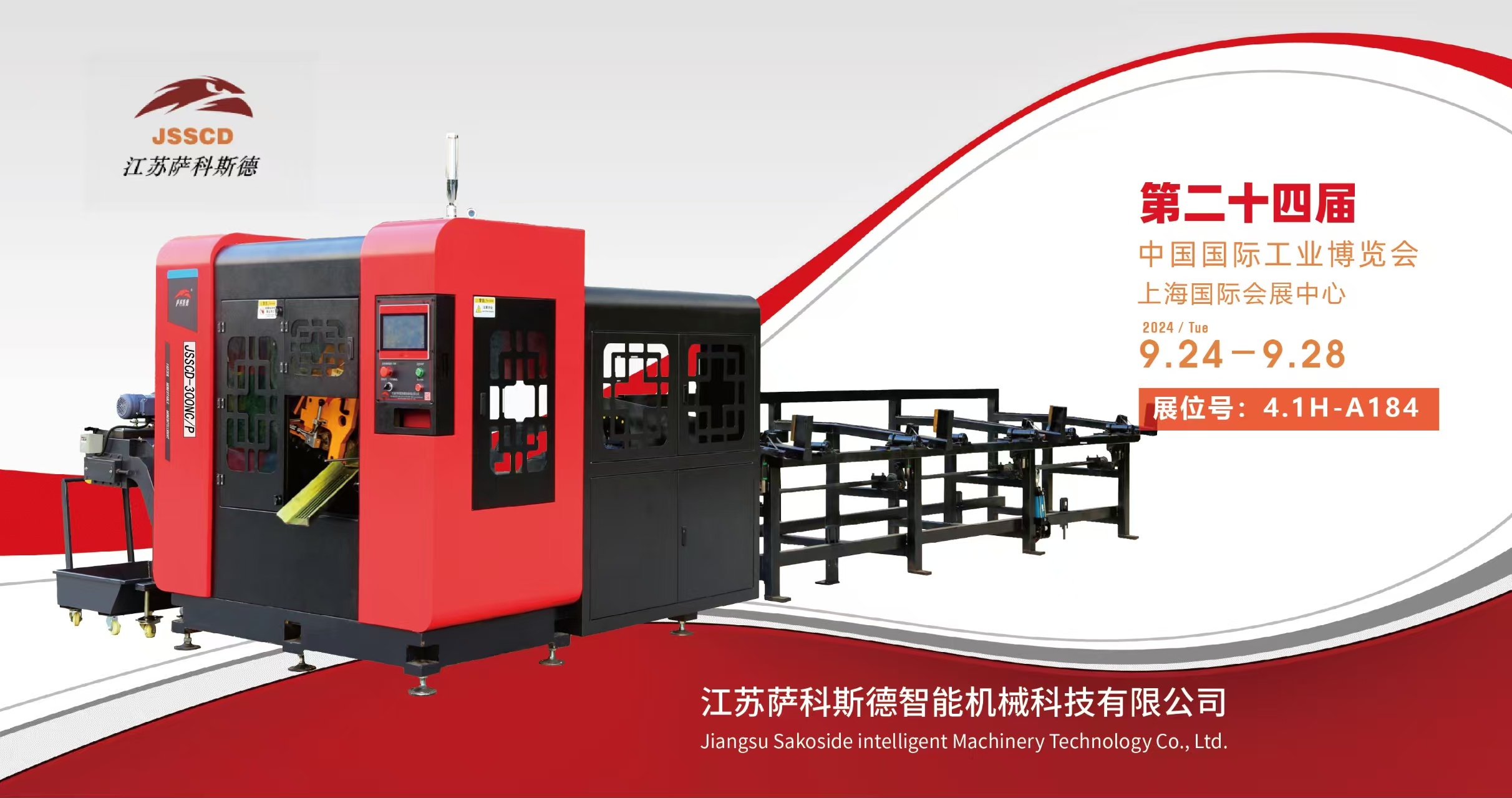

Function of special band sawing machine system on construction site

Release time:

2022-07-04

The function of the special band sawing machine system on the construction site: the hydraulic transmission device is a hydraulic circuit, which is composed of parts and auxiliary parts, such as pumps, valves, cylinders, oil tanks, pipelines, etc., to complete the lifting of the saw beam and clamp the workpiece under electrical control. Through the speed control valve, the stepless speed regulation of the feed speed can be effectively realized to meet the needs of sawing workpieces made of different product materials. The electric control system is a control circuit composed of electric box, control box, junction box, travel switch, electromagnet, etc.

Function of special band sawing machine system on construction site

The function of the special band sawing machine system on the construction site: the hydraulic transmission device is a hydraulic circuit, which is composed of parts and auxiliary parts, such as pumps, valves, cylinders, oil tanks, pipelines, etc., to complete the lifting of the saw beam and clamp the workpiece under electrical control. Through the speed control valve, the stepless speed regulation of the feed speed can be effectively realized to meet the needs of sawing workpieces made of different product materials. The electric control system is a control circuit composed of electric box, control box, junction box, travel switch, electromagnet, etc.

The special band sawing machine on the construction site is used to control the rotation of the saw blade and the lifting of the saw beam. And the workpiece clamping, so that it can be operated according to a certain process. Achieve normal cutting cycle. The lubrication management system shall analyze and lubricate the students according to the requirements of designing the lubrication parts of machine tool equipment (wire brush shaft, worm gear box, movable passing bearing seat, worm bearing, upper and lower shaft of lifting oil cylinder, clamping screw of movable vise sliding surface).) Before starting the lubrication system. The worm wheel and worm in the worm box are lubricated by the No. 30 oil groove and injected through the oil plug hole on the upper part of the worm box. Between. The oil should be changed after one month of use, and then every 3-6 months. The lower part of the worm gear box is provided with an oil drain plug, and the saw blade tensioning mechanism is responsible for the tensioning of the saw blade. The tension of the saw blade should be strictly controlled during use.

Improvement of Saw Wheel Structure of Special Band Sawing Machine on Construction Site

The saw wheel is a pair of wheels to realize the installation of the band saw machine, and it is the main working part to realize the main movement of the society. The lower saw wheel of the band saw is the driving wheel, which must have a large moment of inertia and can act as a flywheel when working. The upper saw wheel is passive and driven by the saw blade. It is required to be lighter. It is synchronized with the saw blade as much as possible to reduce the violent friction and slippage between the saw blade and the saw blade caused by the change of starting braking and sawing resistance. The saw blade is excessively stretched and broken.

(1) The surface of the band saw wheel can be studied by quenching and cold hardening to improve the strength of the saw wheel surface and reduce the friction between the saw wheel and the saw blade.

(2) The surface of the saw wheel is coated with 3-5mm thick rubber, which can effectively reduce the noise of the saw wheel. This teaching method is mostly used in a small band saw machine in a furniture factory.

The structure of the upper saw wheel is changed from spoke type to spoke type, which is not easy to vibrate. The spoke-type upper saw wheel adopts an overall development casting industrial structure to eliminate or reduce the airflow generated by the rotation of the spoke-type upper saw wheel through rotation noise and eddy current noise, and the noise of the whole machine system can be reduced by about 3d B (a).

At present, the main characteristics of the special band sawing machine on the construction site are high feed speed, large size of the saw machine and poor stability of the saw blade. The sawing accuracy is low, and the stability of the saw blade depends on factors such as the tension of the saw blade, the exposed length of the saw blade, the feed direction and the guide device. The saw card is the guiding device of the band saw machine. The utility model can shorten the free length of the working surface of the saw blade, improve the rigidity of the saw blade, reduce the amplitude of the transverse vibration of the saw blade, and keep the saw track straight. The sawing card shall be installed close to the wood being sawn.