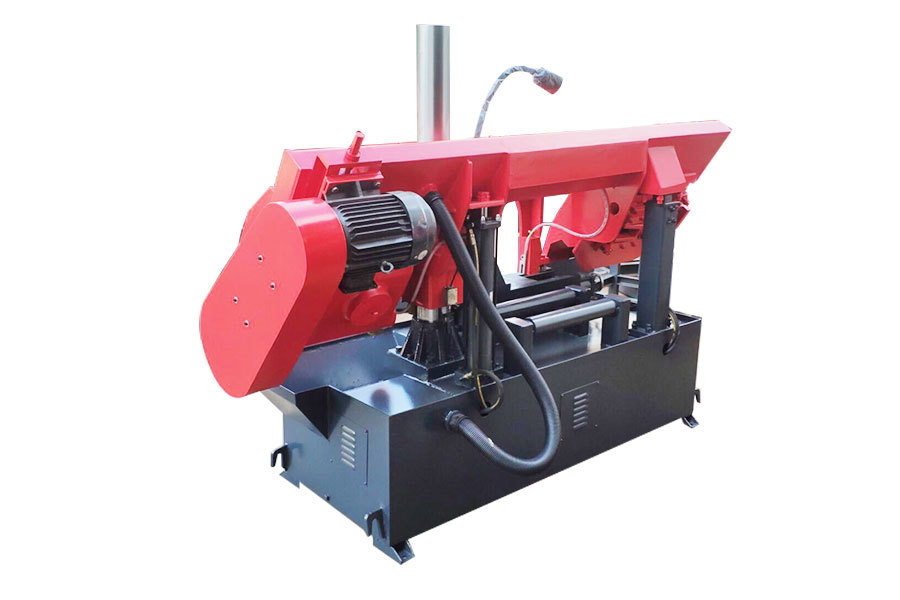

Automatic Processing System for Saw Blade Tension of Special Band Saw Machine on Site

Release time:

2022-06-29

In order to adapt the saw blade to the cutting stress of the wood and its own thermal stress changes, prevent the saw blade from moving and achieve the purpose of stable work, the saw blade on the ordinary band saw machine should be properly treated. The tension is frequent, and the appropriate tension processing technology has high technical content. Relying on experience and tradition, technology is conservative and problems are frequent. As a result, the sawing is not smooth, the sawing accuracy is low, and the sawing machine operator conflicts with the sawing repairer.

Automatic Processing System for Saw Blade Tension of Special Band Saw Machine on Site

In order to adapt the saw blade to the cutting stress of the wood and its own thermal stress changes, prevent the saw blade from moving and achieve the purpose of stable work, the saw blade on the ordinary band saw machine should be properly treated. The tension is frequent, and the appropriate tension processing technology has high technical content. Relying on experience and tradition, technology is conservative and problems are frequent. As a result, the sawing is not smooth, the sawing accuracy is low, and the sawing machine operator conflicts with the sawing repairer. Therefore, many countries are developing a variety of sawing machines that can automatically handle moderate tension.

① Nanjing Forestry University developed an automatic processing saw wheel form suitable for ordinary band saw machines. After production and use, whether it is a saw blade with appropriate tension or a newly used saw blade, it does not need to be treated with appropriate tension. It can be used directly. The saw blade works smoothly and does not leave traces on the copy of the saw back and root., Sawn timber processing quality is good. Because this technology does not change the basic rate structure of the original band saw machine, only the turning of the saw hub surface is easy to popularize and use.

② Ribs are processed on the rim of the special band sawing machine on the construction site. Some modern band saws in Europe are generally sharpened on the rim, and there are two main forms. One is to add two arcs to the rim surface so that they form a convex edge about 1/3 of the wheel width from the working edge; the arc and ridge are formed near the leading edge.

③ There is an annular groove on the edge surface of the saw wheel. These grooves can smoothly remove the air cushion that may be formed on the surface of the saw blade and the rim due to air intrusion, so that the saw blade and the saw wheel are in closer contact, and the working stability of the saw blade is improved.. At the same time, these grooves form a plurality of support points on the surface of the saw blade in the width direction, which is beneficial to prevent the saw blade from sliding backward.

④ The static shaft structure of the saw wheel of the special band sawing machine on the construction site bends under the action of tension, which will lead to excessive radial runout when the saw wheel rotates, resulting in periodic expansion and contraction of the saw blade, sudden stress change and instability. In order to solve this problem, the modern band saw machine generally adopts the static shaft structure, which has good rigidity and is not easy to bend, which is beneficial to improve the stability of the saw wheel and saw blade operation, and can meet the needs of the high-pressure band saw machine. At the same time, the static shaft structure can also be made into a single support form, which is convenient for application in various chain saws.

Saw blade crack is a common phenomenon that cannot be avoided in the use of saw blades. But it has a negative impact on the production of wood. When the crack of the saw blade exceeds the specified length, it will cause an accident and threaten the health of the operator. Therefore, although the repair saw in the repair saw took different measures, although to avoid the saw blade crack, but often due to improper measures, the saw blade is not easy to use, short service life, sawn timber quality problems significantly reduced. In the past, only to meet the requirements of the use of starting, the provisions of the tensile strength, elongation and hardness of the three mechanical properties, but from the point of view of the elimination of hidden dangers, is not complete, especially the toughness of the joinery band saw blade index. Obvious.

The application of repeated bending test is an effective detection method, which has the advantages of simple test device, sensitive defect reflection, convenient operation and short test cycle. The method refers to the national standard GB235-33 metal repeated bending test machine (GWJ-5 type). After appropriate modification, the test paper can be carried out by replacing some parts. Defects can be detected: internal defects of the steel (such as fine cracks, pinching, etc.).

Harmful impurities contained in steel (such as non-metallic inclusions exceeding the standard, grain boundary enrichment of harmful elements, etc.).

Heat treatment defects (such as coarse grains, quenching cracks, network carbides, temper brittleness).

Practice shows that the defects in cold and hot processing can be found at the same time, and when combined with tensile and hardness tests, it can reflect good economic results, reduce the incidence of band saw fracture accidents to a large extent, and promote the special band saw on the construction site. Improve the quality of the machine.